Steel Gratings and Types: A Comprehensive Guide

2025-01-20

Introduction to Steel Gratings

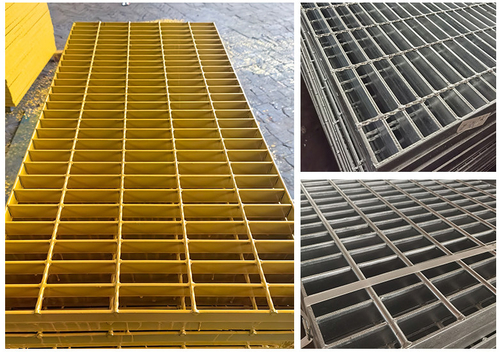

Steel gratings are versatile, strong, and durable materials made from parallel or crossed bars, creating open spaces that allow for air, light, liquids, or debris to pass through. They are highly valued for their exceptional strength-to-weight ratio and ease of fabrication, offering flexible designs for a variety of applications.

Steel gratings are primarily used in industrial and commercial settings and are often applied as platforms, walkways, stair treads, trench covers, and even as decorative elements in building facades. Depending on their manufacturing process, they are categorized into two main types: bar gratings and safety gratings.

Types of Steel Gratings

1. Bar Grating

Bar grating is one of the most widely used types of grating. It is typically made of bearing bars that run parallel to each other, connected by crossbars at right angles. Bar gratings can be fabricated using various methods such as welding, press-locking, and swage-locking, leading to different types of bar grating. The primary types include:

a. Welded Steel Grating

Welded steel grating is the most common and versatile of all industrial gratings. It consists of bearing bars and crossbars that are welded together through resistance welding, creating a rugged, one-piece panel. The welded joints provide strength and rigidity, making it ideal for walkways, safety barriers, drainage covers, platforms, and stair treads. Welded steel gratings come in both plain and serrated surfaces for varying traction needs.

Specifications:

Common sizes include 19-W-2, 19-W-4, 15-W-2, and 15-W-4, where the first number (e.g., 19) refers to the spacing between the bearing bars, and the second number (e.g., 4) refers to the spacing between the crossbars.

b. Press-Locked Steel Grating

Press-locked grating is made by using hydraulic pressure to lock crossbars into slotted bearing bars. This process creates a smooth, durable, and aesthetically pleasing grating. It’s commonly used for architectural purposes, such as building facades, as well as industrial applications like flooring and fencing.

Specifications:

Common sizes include 19-P-2, 19-P-4, 15-P-2, and 15-P-4, with the numbers referring to the spacing between the bars.

c. Swage-Locked Grating

Swage-locked grating, often made from aluminum, is produced by inserting crossbars into pre-punched holes in the bearing bars, then swaging them to form a positive mechanical connection. This grating type is used mainly for architectural applications, such as platform ceilings and outdoor curtain walls.

Specifications:

Common sizes include 19-SG-2, 19-SG-4, 15-SG-2, and 15-SG-4.

2. Safety Grating

Safety grating is specifically designed to enhance safety by providing traction and reducing the risk of slips and falls. This type of grating is typically made from metal sheets that are perforated or cold-stamped to create various patterns. The most common types of safety gratings include:

a. Diamond-Strut Safety Grating

Diamond-strut safety grating features a diamond-shaped pattern that helps to improve traction and prevent slipping. It is typically used in environments where safety is paramount, such as industrial walkways, stair treads, and floors.

Specifications:

Available in various lengths (6000 mm) and widths (120 mm to 480 mm), with a thickness range from 1.5 mm to 2.5 mm.

b. O-Grip Safety Grating

O-grip safety grating is known for its large debossed holes and perforated buttons that provide maximum slip protection. It is suitable for a wide range of applications, including walkways, stair treads, and working platforms in both commercial and industrial settings.

Specifications:

Available in lengths of 4000 mm, with widths ranging from 150 mm to 300 mm and thicknesses from 1.5 mm to 2.5 mm.

c. Traction-Grip Safety Grating

Traction-grip safety grating features hundreds of perforated buttons across its surface, providing excellent slip resistance. This type of grating is ideal for high-traffic areas in industrial environments where safety is a top priority.

Specifications:

Available in lengths up to 6000 mm, with widths ranging from 150 mm to 400 mm and thicknesses from 1.5 mm to 2.5 mm.

Applications of Steel Gratings

Steel gratings have a broad range of applications, providing structural support, enhancing safety, and improving ventilation across various industries. Some common applications include:

Walkways and Platforms: Steel gratings are often used in construction sites, factories, and chemical plants as walkways, providing safe, durable surfaces for workers.

Stair Treads: Steel gratings offer slip-resistant surfaces for stair treads, reducing the risk of accidents.

Ventilation Covers: Gratings are widely used in HVAC systems and machine guarding to allow airflow while providing structural support.

Drainage Covers: Steel gratings are commonly used in drainage systems to provide support and allow water or other liquids to flow freely while preventing debris from entering.

Conclusion

Steel gratings are indispensable in industrial and commercial applications. Their versatility in design, durability, and safety features make them suitable for a wide array of uses, from walkways and platforms to safety barriers and drainage covers. Understanding the differences between bar gratings and safety gratings, as well as the specific types such as welded, press-locked, and swage-locked, will help you choose the right grating solution for your needs.

Whether you are looking for heavy-duty grating for industrial purposes or slip-resistant options for safety, steel gratings offer an excellent combination of strength, safety, and functionality.

For expert advice on selecting the right steel grating, feel free to reach out to our team. We provide high-quality grating solutions tailored to your specific needs.

Read More

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!